- CNC Plasma Cutter

- Portable CNC Plasma

- Gantry CNC Plasma

- Table CNC Plasma

- Pipe CNC Plasma

- CNC Flame Cutter

- Portable CNC Flame Cutting

- Gantry CNC Flame Cutting

- Table CNC Flame Cutting

- Pipe CNC Flame Cutting

- CNC Laser Cutter

- Metal Sheet Cutter

- Portable CNC Cutting

- Gantry CNC Cutting

- Table CNC Cutting

- Metal Pipe Cutter

HSS and Tct Annular Broach Cutter Broaching Magnetic Drill for Metal Sheet

Basic Info

| Model NO. | AC-008 |

| Origin | P. R. China |

| HS Code | 8027509000 |

| Production Capacity | 100, 000PCS/Month |

Product Description

Product Name

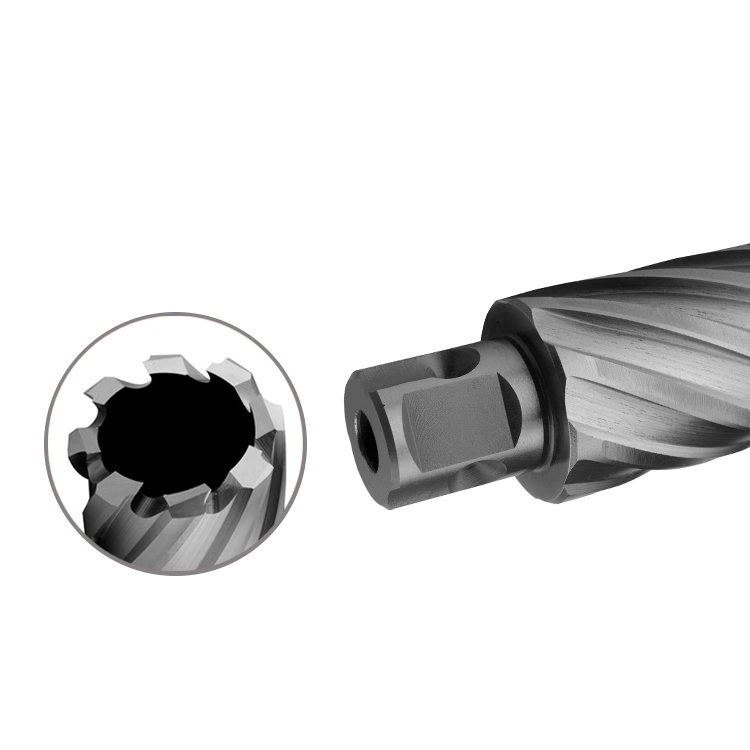

HSS and Tct Annular Broach Cutter Broaching Magnetic Drill for Metal Sheet

Material

HSS Annular Cutter: M2AL High Speed Steel

TCT Annular Cutter: Tungsten Carbide Tip + 45# Steel BodyShank

Weldon Shank (Universal Shank and Fein Shank are available)

Surface Finish

HSS Annular Cutter: Bright, TIN coating and Titanium coating are available

TCT Annular Cutter: Sand BlastedPackageOne Piece in One Plastic Tube

Features

HSS Annular Cutter:

1.Made of high quality & super tough high speed steel with multi-cut geometry for ply-cutting and lower friction to reach better endurance and less breakage ;

2.Suitable for steel (such as T-brackets, large sheets), cast iron, non-ferrous and light metals;

3.Optimised cutting edge geometry for increased cutting performances and reduced cutting forces;

4.The effective cutting angles are designed for universal use in various sorts of steel;

5.Improved removal of chips thanks to U-shaped recesses. The specific geometry of the recess reduces the thermal load on the HSS core drill as the heat created in cutting is removed with the chips to a very great extent;

6.Reduction of the friction between the HSS core drill and the workpiece thanks to optimised spiral-shaped guide chamfers;

TCT Annular Cutter:

1.Tungsten carbide tipped annular cutters combine extreme hardness and durability with a wide range of possible applications in a convincing product.

2.Suitable for steel (such as T-brackets, large sheets), cast iron, non-ferrous and light metals;

3.Unique tooth geometry, cutting teeth specially grinding by CNC Machine to assure all of teeth in same level,allows for better centering and faster cutting;

4.Thin wall design enables cutters to cut faster and more efficiently by removing less material during drilling;

5.Shorter flute design allows for chips to fall freely from cutter

| Dia | Shank | Cutting Depth | |

| 12-60/mm | 19.05mm | 25mm | 50mm |

| 61-100/mm | 31.75mm | 1' | 2' |

| 1/2''-2-1/3'' | 3/4'' | 75mm | 100mm |

| 2-1/3''-4'' | 1-1/4'' | 3'' | 4'' |