Category

- CNC Plasma Cutter

- Portable CNC Plasma

- Gantry CNC Plasma

- Table CNC Plasma

- Pipe CNC Plasma

- CNC Flame Cutter

- Portable CNC Flame Cutting

- Gantry CNC Flame Cutting

- Table CNC Flame Cutting

- Pipe CNC Flame Cutting

- CNC Laser Cutter

- Metal Sheet Cutter

- Portable CNC Cutting

- Gantry CNC Cutting

- Table CNC Cutting

- Metal Pipe Cutter

Portable Mini CNC Head Pipe Plasma Cutting Laser Cutting Metal Module Kit Machined

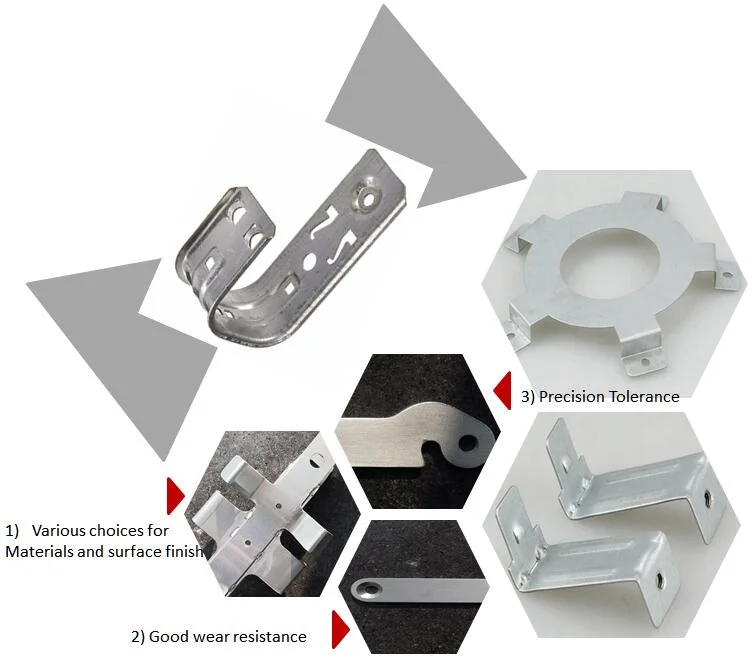

Overview Custom stainless steel sheet carbon steel precision stamping Product Display Only we have drawings or samples,

Basic Info

| Model NO. | Laser Cutting |

| Delivery | 30-35 Days |

| Package | Wooden Pallet/ Iron Pallet/ Carton |

| MOQ | 5000 |

| Surface | Brushed |

| Grade | Stainless Steel/Bronze |

| Thickness | 1.5mm |

| Ra | 2.3 |

| Certificate | ISO9000 |

| Drawing | Step/Pdf |

| Transport Package | Wooden Case |

| Specification | OEM |

| Trademark | Xinghe |

| Origin | Qingdao |

| Production Capacity | 1000t/Year |

Product Description

Custom stainless steel sheet carbon steel precision stamping| Equipment | Set | Items | Description |

| 160T punching machine | 1 | Process | Stamping |

| 110T punching machine | 2 | Mold Material | Cr12 |

| 60T punching machine | 3 | Mold Life | 300K Times |

| 40T punching machine | 1 | Package | All our products will be well packed to keep off damage or moisture. |

| Hydraulic shearing machine | 2 | 1.. PlasticBag+ Carton Box + Wooden Case | |

| Hydraulic rivet machine | 1 | 2..Packing according to customer design requirement |

Only we have drawings or samples, we can custom metal parts for you.

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)2) Checking the details before the production line operated3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)4) Checking the goods after they are finished---- Final quality control(FQC)5) Checking the goods after they are finished-----Outgoing quality control(OQCAll of our operations are strictly compliant with ISO 9001: 2008 guidelinesWe own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray

FAQS

1.How can I get the quotation?Please give us your drawing,quantity,weight and material of the product.2.If you don't have the drawing,can you make drawing for me?Yes,we are able to make the drawing of your sample duplicate the sample.3.When can I get the sample and your main order time?Sample time: 35-40 days after start to make mold. Order time: 35-40 days, the accurate time depends on product.4.What is your payment method?Tooling:100% T/T advanced Order time:50% deposit,50%to be paid before shipment.5.Which kind of file format you can read?PDF, IGS, DWG, STEP, MAX6.What is your surface treatment?Including: powder coating, sand blasting, painting, polishing, acid pickling, anodizing, enamel, zinc plating, hot-dip galvanizing, electrophoresis, chrome plating.7.What is your way of packing?Normally we pack goods according to customers' requirements.