Category

- CNC Plasma Cutter

- Portable CNC Plasma

- Gantry CNC Plasma

- Table CNC Plasma

- Pipe CNC Plasma

- CNC Flame Cutter

- Portable CNC Flame Cutting

- Gantry CNC Flame Cutting

- Table CNC Flame Cutting

- Pipe CNC Flame Cutting

- CNC Laser Cutter

- Metal Sheet Cutter

- Portable CNC Cutting

- Gantry CNC Cutting

- Table CNC Cutting

- Metal Pipe Cutter

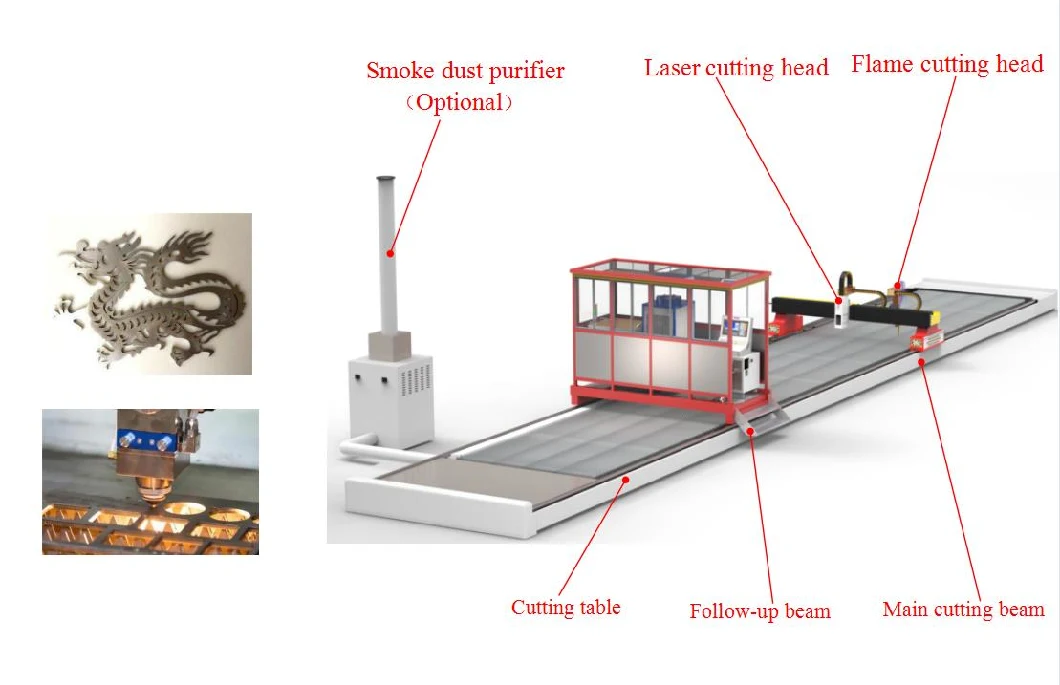

Big Fiber Laser CNC Cutting Machine Gantry, Iron Aluminium Carbon Steel Metal Alloy Cutter, Equipment, up to 30mx16m, Fiber Laser Plasma Cutting Machine

Package size per unit product 1200.00cm * 300.00cm * 50.00cm Gross weight per unit product 2000.000kg Dual beams large f

Basic Info

| Model NO. | ZLQ-BGL |

| After-sales Service | Offer |

| Warranty | 1 Year |

| Application | Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry |

| Cooling System | Water Cooling |

| Technical Class | Continuous Wave Laser |

| Applicable Material | Metal |

| Structure Type | Desktop |

| Laser Classification | Fiber Laser |

| Laser Technology | Laser Flame Cutting |

| Cutting Application | Metal Plate Cutting |

| Control System | Cypcut/Weihong |

| Cutting Torch | Laser/Plasma/Flame |

| Cutting Materials | CS, Ss, Alu, Copperm, Metal Alloy |

| Cutting Thickness | 0.1~200mm |

| Machine Precision | 0.02mm |

| Cutting Area | 3m*1.5m/6m*2.5m/Customize |

| Laser Brand | Raycus/Max/Feibo |

| Laser Power | 500W~20000W |

| Plasma(Option) | Huarong/Huayuan/Hyperthem |

| Plasma Current | 65A/85A/120A/200A/300A/400A/500A |

| Flame Gas(Option) | Oxy& Acetylene/Propane |

| Drive & Motor | Servo Driver+Motor |

| Work Voltage | 220V/380V/415V |

| Certification | CE&ISO |

| Transport Package | Seaworthy Woodencase |

| Specification | International standard |

| Trademark | LANSUN |

| Origin | China |

| HS Code | 84569010 |

| Production Capacity | 800 Sets/ Year |

Packaging & Delivery

Package size per unit product 1200.00cm * 300.00cm * 50.00cm Gross weight per unit product 2000.000kgProduct Description

Dual beams large format laser CNC cutting machineProduct brief

Multifunctional cutting combination between laser cutting and flame cutting . Brief on laser cutting1. Due to the advantages of metal laser cutting, relative to flame and plasma cutting, has been widely used in the field of metal cutting. 2. In terms to the current laser cutting technology, cutting 40mm~60mm thick carbon steel plate with laser will not be prevailing over flame, no matter considering of the efficiency and surface quality, but the cost greatly increased. 3. Laser is not yet suitable for cutting 60mm carbon steel plate. . Combination with laser and flame cutting1.As a result of several the above-mentioned reasons, currently, multifunctional combination equipped with laser cutting and flame cutting has become the current trend, and the advantages of two cutting methods have been fully played. 2. 3KW or 6KW laser combined with flame cutting will be the most economical and applicable scheme, use laser cutting for carbon steel no thicker than 20mm, and flame cutting for those thicker than 20mm; Flame cutting with two torches will be most effective. In order to obtain the cutting efficiency of thick plate with flame cutting, it can be configured with 2 flame heads.

. Cost comparison on different configured equipment1.On the basis of laser cutting, adding flame cutting function requires increased equipment cost, about $770-1230$ . 2.To increase the cutting capacity, the cost of increasing the laser power is about me $3076 to $4180 per KW.

There is a the comparison table between flame and laser cutting as below, in which there lists the laser power and cutting speed required by different carbon steel thickness. It can be a reference for the user to make the decision on choosing equipment. This is also where the suggestions we gave earlier to choose machines comes from.

Main technical parameters

| Item | Parameters |

| Power for fiber laser optional | 1000W-30000W |

| Cutting length | 12m-40m |

| Cutting width | 3m-6m |

| Cutting head stroke | 150mm |

| X/Y axis positioning accuracy | ±0.03mm/m |

| X/Y axis repeated positioning accuracy | ±0.03mm |

| X,Y Max. Running speed | 12m/min |

| Cutting thickness by flame (Optional) | CS 5-250mm |

Wuhan Lansun brief introduction

Who we are Wuhan Lansun is a high-tech enterprise transformed from the scientific research achievements by well-known professors from China University of Geosciences, specializing in the R&D and production of CNC cutting and Automation technology machines for nearly 30 years. It consists of two companies, Wuhan Lansun Technology CO., LTD and Wuhan Lansun CNC CO., LTD. Wuhan Lansun has a R & D and production base of 27,000 square meters in East Lake Development Zone, Wuhan City. Wuhan Lansun has a complete set of production process facilities, as well as R & D department, after-sales service department and quality assurance department. Please refer to below picture for more details.Production Technology

In order to ensure product quality, our company has a complete production process. The productsare annealed in furnaces to ensure the accuracy even after being used for very long time. And the surfaceis shot blasted after powder coating/bake painting to ensure better paint adhesion. Moreover, powdercoating/bake painting on surface is far more beautiful and durable than ordinary self-drying paint. Forthe full set of the production process, please refer to below picture.

Patents and Certificates

In order to ensure product quality, our company has a complete production process. The productsare annealed in furnaces to ensure the accuracy even after being used for very long time. And the surfaceis shot blasted after powder coating/bake painting to ensure better paint adhesion. Moreover, powdercoating/bake painting on surface is far more beautiful and durable than ordinary self-drying paint. For thefullset of the production process, please refer to below picture.

Our Sales

The company has nearly 10,000 domestic and foreign users, the products are exported to Germany,the United States,Britain, Russia, Japan, India and other dozens of countries and regions.

After-sales service

FAQ

1. Are you factory or foreign trade company?

We are over 20 years old manufacturers, large-scale factory of CNC cutting machine.

2. Where is your factory located? How can I visit there?

Our factory is located in Wuhan, Hubei. We will meet you at airport or train station. Warmly welcome to visit us!

3. What's the quality of your products?

We are very focused on the quality of the products, All spare parts of this machine come with best brand and best quality, after completing the installation we will test the machine for 48 hours.Our factory has gained CE, ISO9001 authentication.

4. What shall we do if don' t know how to operate your machine after bought from you?

We have detailed installation and operating instructions attached, also comes with video, it is very simple. We have telephone and email support at 24 hours a day.

5. What other things also need after we bought your machines?

(1) With flame cutting: oxygen and fuel gas.(2) With plasma cutting: air compressor. Plasma power is purchased by us, so that we can debug online, and we all need very goodplasma power to ensure quality.

6. What are your payment terms?

We support T/T, L/C, Western Union and so on. Other ways can also be received after we both sides discussion and agreement.

7. What to do if the machine has a problem?

12 hours timely response of mail and phone calls.In 12 months, if parts fail, we offer free replacement (except customer reasons). 8.What is the advantages of this model machine?

1).Integral one-time forming aluminum alloy longitudinal chassis and beam, better stability, durable and deformation free;2).Equipped with Chengdu brand plasma power lgk130A, it can cut carbon steel 16mm continuously for a long time;3).For the plasma cutting,the height controller adopt the micro arc voltage can be adjusted automatically to adjust the distance between the cutting nozzle and the steel plate;4).Competitive price.